Mathematics, 12.04.2021 22:40 TylieW

Consider a manufacturing process that is producing hypodermic needles that will be used for blood donations. These needles need to have a diameter of 1.65 mm—too big and they would hurt the donor (even more than usual), too small and they would rupture the red blood cells, rendering the donated blood useless. Thus, the manufacturing process would have to be closely monitored to detect any significant departures from the desired diameter. During every shift, quality control personnel take a random sample of several needles and measure their diameters. If they discover a problem, they will stop the manufacturing process until it is corrected. For now, suppose that a "problem" is when the sample average diameter turns out to be statistically significantly different from the target of 1.65 mm.

Answers: 1

Another question on Mathematics

Mathematics, 21.06.2019 18:30

Factor k2 - 17k + 16. a.(k - 2)(k - 8) b.(k - 1)(k + 16) c.(k - 1)(k - 16)

Answers: 1

Mathematics, 21.06.2019 20:30

Aswimming pool measures 22ft by 12ft and is 4ft deep. if the pool is being filled at 2.5 cubic ft per minute, how long will it take to fill the pool?

Answers: 1

Mathematics, 21.06.2019 22:30

Find the condition that the zeros of the polynomial f(x) = x^3+3px^2+3px+r may be in a.p.

Answers: 1

Mathematics, 21.06.2019 23:30

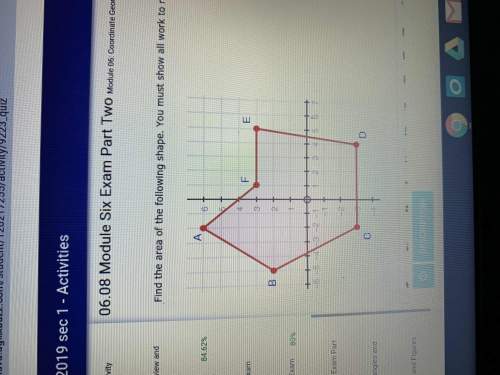

For the feasibility region shown below find the maximum value of the function p=3x+2y

Answers: 3

You know the right answer?

Consider a manufacturing process that is producing hypodermic needles that will be used for blood do...

Questions

Health, 20.07.2019 14:30

Chemistry, 20.07.2019 14:30

Biology, 20.07.2019 14:30

Biology, 20.07.2019 14:30

Physics, 20.07.2019 14:30

Biology, 20.07.2019 14:30

English, 20.07.2019 14:30

Biology, 20.07.2019 14:30

Biology, 20.07.2019 14:30