Engineering, 09.04.2021 04:10 sleepqueen

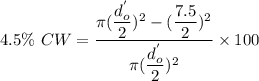

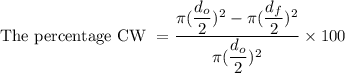

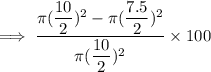

A cylindrical rod of brass originally 10 mm in diameter is to be cold worked by drawing. The circular cross section will be maintained during deformation. A cold-worked tensile strength in excess of 380 MPa and a ductility of at least 15 %EL are desired. Furthermore, the final diameter must be 7.5 mm. Explain how this may be accomplished. Use the graphs given in previous question.

Answers: 2

Another question on Engineering

Engineering, 03.07.2019 15:10

Apiston-cylinder with a volume of 0.25 m3 holds 1 kg of air (r 0.287 k/kgk) at a temperature of 100 c. heat transfer to the cylinder causes an isothermal expansion of the piston until the volume triples. how much heat is added to the piston-cylinder?

Answers: 3

Engineering, 04.07.2019 18:10

Coiled springs ought to be very strong and stiff. si3n4 is a strong, stiff material. would you select this material for a spring? explain.

Answers: 2

Engineering, 04.07.2019 18:10

Asingle-geared blanking press has a stroke of 200 mm and a rated capacity of 320 kn. a cam driven ram is assumed to be capable of delivering the full press load at constant force during the last 15 percent of a constant-velocity stroke. the camshaft has an average speed of 90 rev/min and is geared to the flywheel shaft at a 6: 1 ratio. the total work done is to include an allowance of 16 percent for friction a) estimate the maximum energy fluctuation b) find the rim weight for an effective diameter of 1.2 m and a coefficient of speed fluctuation of 0.10

Answers: 1

Engineering, 04.07.2019 18:10

During a steady flow process, the change of energy with respect to time is zero. a)- true b)- false

Answers: 2

You know the right answer?

A cylindrical rod of brass originally 10 mm in diameter is to be cold worked by drawing. The circula...

Questions

History, 12.07.2019 15:50

Mathematics, 12.07.2019 16:00

Mathematics, 12.07.2019 16:00

English, 12.07.2019 16:00

Computers and Technology, 12.07.2019 16:00

Mathematics, 12.07.2019 16:00

Biology, 12.07.2019 16:00

English, 12.07.2019 16:00

Chemistry, 12.07.2019 16:00

History, 12.07.2019 16:00

History, 12.07.2019 16:00

Spanish, 12.07.2019 16:00

Mathematics, 12.07.2019 16:00

= 10 mm

= 10 mm 7.5 mm

7.5 mm

= 21.5 CW

= 21.5 CW ; Then:

; Then: