Engineering, 15.02.2021 20:30 laywah4

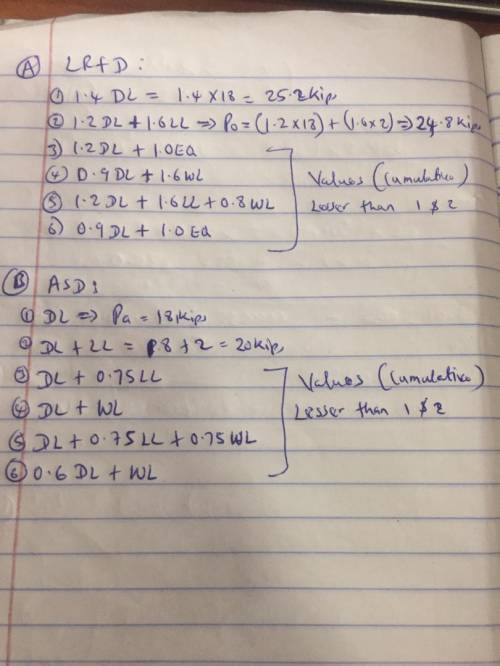

A tension member must be designed for a service dead load of 18 kips and a service live load of 2 kips.

Required:

a. If load and resistance factor design is used, determine the maximum factored load (required strength) and the controlling AISC load combination.

b. If allowable strength design is used, determine the maximum load (required strength) and the controlling AISC load combination.

Answers: 3

Another question on Engineering

Engineering, 03.07.2019 15:10

Apiston-cylinder with a volume of 0.25 m3 holds 1 kg of air (r 0.287 k/kgk) at a temperature of 100 c. heat transfer to the cylinder causes an isothermal expansion of the piston until the volume triples. how much heat is added to the piston-cylinder?

Answers: 3

Engineering, 04.07.2019 18:10

The temperature of air decreases as it is compressed by an adiabatic compressor. a)- true b)- false

Answers: 2

Engineering, 04.07.2019 18:10

Fluids at rest possess no flow energy. a)- true b)- false

Answers: 3

Engineering, 04.07.2019 18:10

Asingle-geared blanking press has a stroke of 200 mm and a rated capacity of 320 kn. a cam driven ram is assumed to be capable of delivering the full press load at constant force during the last 15 percent of a constant-velocity stroke. the camshaft has an average speed of 90 rev/min and is geared to the flywheel shaft at a 6: 1 ratio. the total work done is to include an allowance of 16 percent for friction a) estimate the maximum energy fluctuation b) find the rim weight for an effective diameter of 1.2 m and a coefficient of speed fluctuation of 0.10

Answers: 1

You know the right answer?

A tension member must be designed for a service dead load of 18 kips and a service live load of 2 ki...

Questions

Mathematics, 15.03.2022 05:50

English, 15.03.2022 05:50

Chemistry, 15.03.2022 05:50

Mathematics, 15.03.2022 06:00

Business, 15.03.2022 06:00

Physics, 15.03.2022 06:00

Chemistry, 15.03.2022 06:00

Mathematics, 15.03.2022 06:00

Mathematics, 15.03.2022 06:00

English, 15.03.2022 06:00

History, 15.03.2022 06:00