Engineering, 24.04.2020 03:22 austinmiller3030

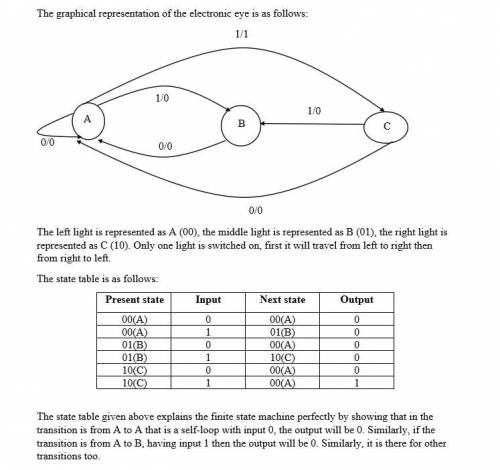

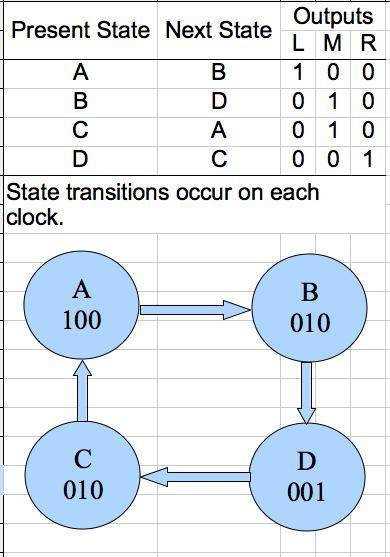

A friend would like you to build an "electronic eye" for use as a fake security device. The device consists of three lights lined up in a row, controlled up by the outputs left, Middle, and Right, which if asserted, indicate that a light should be on. Only one light is on at a time, and the light moves from left to right. Only one light is on at a time, and the light moves from left to right and then from right to left, thus scaring away thieves who believe that the device is monitoring their activity.

Draw the graphical representation for the finite state machine used to specify the electronic eye. Note that the rate of the eyes movement will be controlled by the clock speed (which should not be too great) and there are essentially no inputs.

Answers: 2

Another question on Engineering

Engineering, 03.07.2019 15:10

Heat is added to a piston-cylinder device filled with 2 kg of air to raise its temperature 400 c from an initial temperature of t1 27 cand pressure of pi 1 mpa. the process is isobaric process. find a)-the final pressure p2 b)-the heat transfer to the air.

Answers: 1

Engineering, 04.07.2019 18:10

Afull journal bearing has a journal diameter of 27 mm, with a unilateral tolerance of -0.028 mm. the bushing bore has a diameter of 27.028 mm and a unilateral tolerance of 0.04 mm. the l/d ratio is 0.5. the load is 1.3 kn and the journal runs at 1200 rev/min. if the average viscosity is 50 mpa-s, find the minimum film thickness, the power loss, and the side flow for the minimum clearance assembly.

Answers: 1

Engineering, 04.07.2019 18:10

Assuming compressible flow of air and that the measurements are done at flagstaff a pitot static tube that gives the difference of total and static pressure measures 0.35 m of mercury. what is the velocity of air? assume the temperature to be 300k. (submit your excel or matlab calculation sheet)

Answers: 1

Engineering, 04.07.2019 18:10

Aturning operation is performed with following conditions: rake angle of 12°, a feed of 0.35 mm/rev, and a depth of cut of 1.1 mm. the work piece is aluminum alloy 6061 with t6 heat treatment (a16061-t6). the resultant chip thickness was measured to be 1.0 mm. estimate the cutting force, fc. use shear stress of 207 mpa and coefficient of friction on the tool face of 0.6.

Answers: 1

You know the right answer?

A friend would like you to build an "electronic eye" for use as a fake security device. The device c...

Questions

Mathematics, 04.02.2021 18:30

Arts, 04.02.2021 18:30

Mathematics, 04.02.2021 18:30

Spanish, 04.02.2021 18:30

Mathematics, 04.02.2021 18:30

Mathematics, 04.02.2021 18:30

Mathematics, 04.02.2021 18:30

History, 04.02.2021 18:30

English, 04.02.2021 18:30