Engineering, 21.04.2020 23:29 YuNgJoKeR

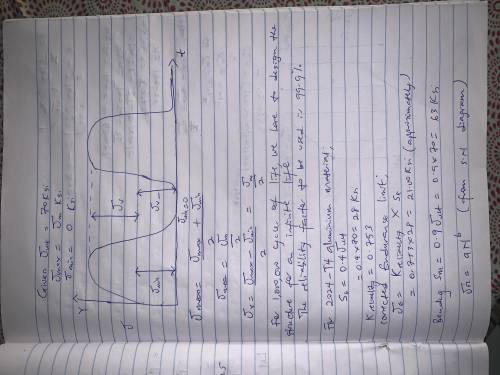

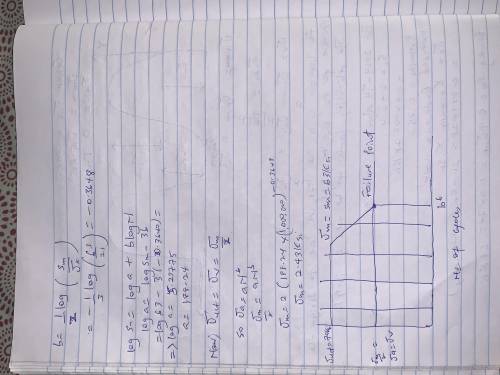

- Consider a 2024-T4 aluminum material with ultimate tensile strength of 70 ksi. In a given application, a component of this material is to experience ‘released tension’ stress cycling between minimum and maximum stress level of 0 and σmax ksi. As an engineer, you want to have 99.9% chance that the component does not fail before 1,000,000 cycles. What should be the value of σmax?

Answers: 2

Another question on Engineering

Engineering, 04.07.2019 18:10

Aplate clutch has a single pair of mating friction surfaces 250-mm od by 175-mm id. the mean value of the coefficient of friction is 0.30, and the actuating force is 4 kn. a) find the maximum pressure and the torque capacity using the uniform-wear model. b) find the maximum pressure and the torque capacity using the uniform-pressure model.

Answers: 3

Engineering, 04.07.2019 18:10

Which of the following refers to refers to how well the control system responds to sudden changes in the system. a)-transient regulation b)- distributed regulation c)-constant regulation d)-steady-state regulation

Answers: 1

Engineering, 04.07.2019 18:10

Calculate the bore of a cylinder that has a stroke of 18 inches and an extension time of 6 seconds at a flow rate of 4 gal/min.

Answers: 3

Engineering, 04.07.2019 18:10

Aturning operation is performed with following conditions: rake angle of 12°, a feed of 0.35 mm/rev, and a depth of cut of 1.1 mm. the work piece is aluminum alloy 6061 with t6 heat treatment (a16061-t6). the resultant chip thickness was measured to be 1.0 mm. estimate the cutting force, fc. use shear stress of 207 mpa and coefficient of friction on the tool face of 0.6.

Answers: 1

You know the right answer?

- Consider a 2024-T4 aluminum material with ultimate tensile strength of 70 ksi. In a given applicat...

Questions

Mathematics, 05.05.2020 10:05

Biology, 05.05.2020 10:05

Mathematics, 05.05.2020 10:05

Social Studies, 05.05.2020 10:05

English, 05.05.2020 10:05

History, 05.05.2020 10:05

Health, 05.05.2020 10:05