Engineering, 19.03.2020 02:47 plb2007

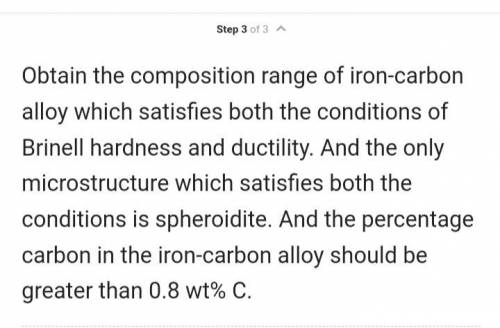

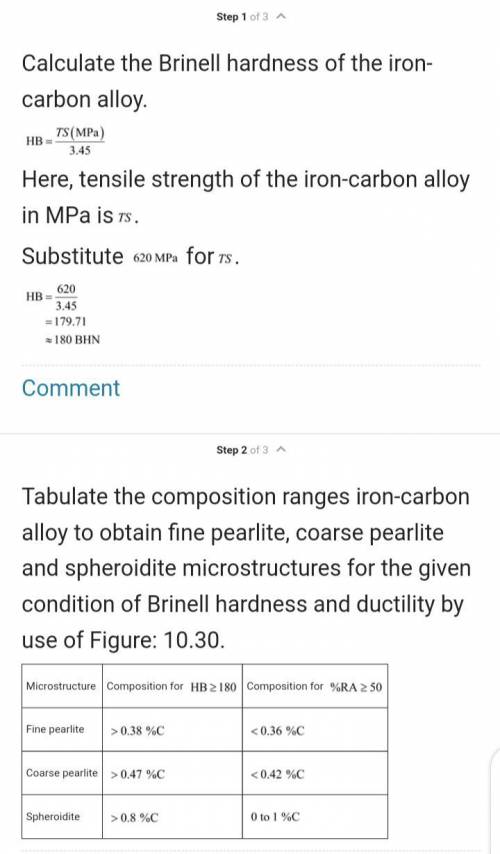

S it possible to produce an iron–carbon alloy that has a minimum tensile strength of 620 MPa (90,000 psi) and a minimum ductility of 50% RA? If so, what will be its composition and microstructure (coarse and fine pearlites and spheroidite are alternatives)? If this is not possible, explain why.

Answers: 3

Another question on Engineering

Engineering, 04.07.2019 18:10

Aplate clutch has a single pair of mating friction surfaces 250-mm od by 175-mm id. the mean value of the coefficient of friction is 0.30, and the actuating force is 4 kn. a) find the maximum pressure and the torque capacity using the uniform-wear model. b) find the maximum pressure and the torque capacity using the uniform-pressure model.

Answers: 3

Engineering, 04.07.2019 18:10

Give heat transfer applications for the following, (i) gas turbines (propulsion) ) gas turbines (power generation). (iii) steam turbines. (iv) combined heat and power (chp). (v) automotive engines

Answers: 1

Engineering, 04.07.2019 18:10

Different types of steels contain different elements that alter the characteristics of the steel. for each of the following elements, explain what the element does when alloyed with steel.

Answers: 2

Engineering, 04.07.2019 18:10

The flow rate of air through a through a pipe is 0.02 m5/s. a pitot static tube is placed in the flow. the radius of the pitot static tube is 1 mm. assuming the flow to be steady and the air to be at 300k, calculate the difference in total and static pressure if the diameter of the pipe is: (a) d 0.1 m d 0.05 m (c) d 0.01 m

Answers: 2

You know the right answer?

S it possible to produce an iron–carbon alloy that has a minimum tensile strength of 620 MPa (90,000...

Questions

English, 18.12.2020 04:00

Arts, 18.12.2020 04:00

Mathematics, 18.12.2020 04:00

Computers and Technology, 18.12.2020 04:00

Biology, 18.12.2020 04:00

Mathematics, 18.12.2020 04:00

Social Studies, 18.12.2020 04:00

Chemistry, 18.12.2020 04:00

Biology, 18.12.2020 04:00

History, 18.12.2020 04:00

Chemistry, 18.12.2020 04:00

Advanced Placement (AP), 18.12.2020 04:00

Mathematics, 18.12.2020 04:00