Engineering, 13.03.2020 04:34 sitstareplay7073

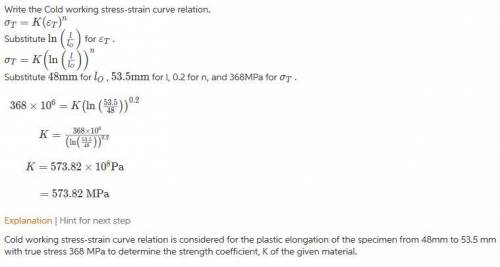

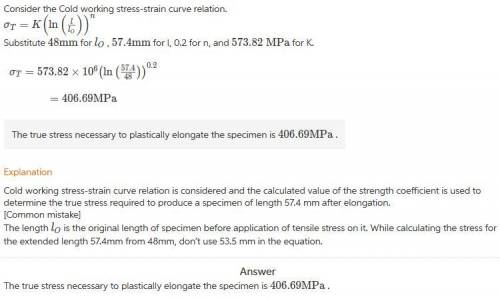

A cylindrical specimen of a metal alloy 48.8 mm long and 9.09 mm in diameter is stressed in tension. A true stress of 327 MPa causes the specimen to plastically elongate to a length of 55.0 mm. If it is known that the strain-hardening exponent for this alloy is 0.3, calculate the true stress (in MPa) necessary to plastically elongate a specimen of this same material from a length of 48.8 mm to a length of 57.6 mm

Answers: 2

Another question on Engineering

Engineering, 03.07.2019 14:10

If the thermal strain developed in polyimide film during deposition is given as 0.0044. assume room temperature is kept at 17.3 c, and thermal coefficient of expansion for the film and the substrate are 54 x 10^-6c^-1 and 3.3 x 10^-6c^-1respectively. calculate the deposition temperature.

Answers: 3

Engineering, 04.07.2019 18:10

Aloaded platform of total mass 500 kg is supported by a dashpot and by a set of springs of effective stiffness 72 kn/m. it is observed that when the platform is depressed through a distance x = 12.5 cm below its equilibrium position and then released without any initial velocity; it reaches its equilibrium position in the shortest possible time without overshoot. find the position and velocity of the loaded platform 0.10 sec. after its release. if a further load of 400 kg is added to the platform, find, i) the frequency of damped vibrations, and i) the amplitude of vibration after 2 complete oscillations, given that the initial amplitude is 15 cm.

Answers: 1

Engineering, 04.07.2019 18:10

Afull journal bearing has a journal diameter of 27 mm, with a unilateral tolerance of -0.028 mm. the bushing bore has a diameter of 27.028 mm and a unilateral tolerance of 0.04 mm. the l/d ratio is 0.5. the load is 1.3 kn and the journal runs at 1200 rev/min. if the average viscosity is 50 mpa-s, find the minimum film thickness, the power loss, and the side flow for the minimum clearance assembly.

Answers: 1

Engineering, 04.07.2019 18:10

For the closed feedwater heater below, feedwater enters state 3 at a pressure of 2000 psia and temperature of 420 °f at a rate of ix10 ibhr. the feedwat extracted steam enters state 1 at a pressure of 1000 psia and enthalpy of 1500 btu/lbm. the extracted er leaves at an enthalpy of 528.7 btu/lbm steam leaves as a saturated liquid. (16) a) determine the mass flow rate of the extraction steam used to heat the feedwater (10) b) determine the terminal temperature difference of the closed feedwater heater

Answers: 3

You know the right answer?

A cylindrical specimen of a metal alloy 48.8 mm long and 9.09 mm in diameter is stressed in tension....

Questions

Mathematics, 25.05.2021 23:30

Biology, 25.05.2021 23:30

History, 25.05.2021 23:30

Mathematics, 25.05.2021 23:30

Social Studies, 25.05.2021 23:30

Spanish, 25.05.2021 23:30

Mathematics, 25.05.2021 23:30

Mathematics, 25.05.2021 23:30

Computers and Technology, 25.05.2021 23:30

Mathematics, 25.05.2021 23:30

Mathematics, 25.05.2021 23:30

History, 25.05.2021 23:30

Mathematics, 25.05.2021 23:30

Mathematics, 25.05.2021 23:30

Mathematics, 25.05.2021 23:30

Mathematics, 25.05.2021 23:30