Engineering, 16.11.2019 06:31 kdawg203

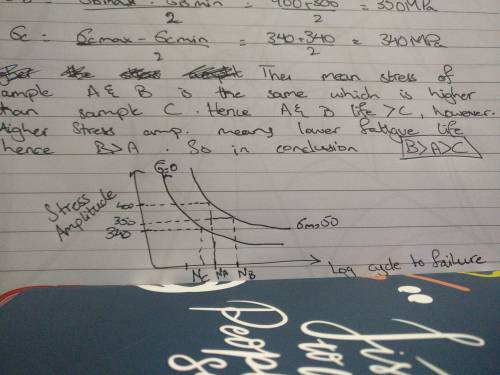

8.26 three identical fatigue specimens (denoted a, b, and c) are fabricated from a nonferrous alloy. each is subjected to one of the maximum-minimum stress cycles listed below; the frequency is the same for all three tests. specimenmax (mpa) min (mpa) a +450 –350 b +400 –300 c +340 –340 (a) rank the fatigue lifetimes of these three specimens from the longest to the shortest. (b) now justify this ranking using a schematic s–n plot.

Answers: 1

Another question on Engineering

Engineering, 04.07.2019 18:10

Aloaded platform of total mass 500 kg is supported by a dashpot and by a set of springs of effective stiffness 72 kn/m. it is observed that when the platform is depressed through a distance x = 12.5 cm below its equilibrium position and then released without any initial velocity; it reaches its equilibrium position in the shortest possible time without overshoot. find the position and velocity of the loaded platform 0.10 sec. after its release. if a further load of 400 kg is added to the platform, find, i) the frequency of damped vibrations, and i) the amplitude of vibration after 2 complete oscillations, given that the initial amplitude is 15 cm.

Answers: 1

Engineering, 04.07.2019 18:10

Assuming compressible flow of air and that the measurements are done at flagstaff a pitot static tube that gives the difference of total and static pressure measures 0.35 m of mercury. what is the velocity of air? assume the temperature to be 300k. (submit your excel or matlab calculation sheet)

Answers: 1

Engineering, 04.07.2019 18:10

What are the two (02) benefits, which may result from a successful implementation of preventive maintenance (pm) program in an organization? (clo3)a)- lean manufacturing b)-overlapping responsibilities c)-the planner is not qualified d)-accurate contractor information e)-reduction in equipment redundancies f)-accurate stores information

Answers: 3

Engineering, 04.07.2019 18:10

Aturning operation is performed with following conditions: rake angle of 12°, a feed of 0.35 mm/rev, and a depth of cut of 1.1 mm. the work piece is aluminum alloy 6061 with t6 heat treatment (a16061-t6). the resultant chip thickness was measured to be 1.0 mm. estimate the cutting force, fc. use shear stress of 207 mpa and coefficient of friction on the tool face of 0.6.

Answers: 1

You know the right answer?

8.26 three identical fatigue specimens (denoted a, b, and c) are fabricated from a nonferrous alloy....

Questions

Mathematics, 21.04.2021 18:50

History, 21.04.2021 18:50

English, 21.04.2021 18:50

Mathematics, 21.04.2021 18:50

Computers and Technology, 21.04.2021 18:50

Mathematics, 21.04.2021 18:50

English, 21.04.2021 18:50

Chemistry, 21.04.2021 18:50

Mathematics, 21.04.2021 18:50

English, 21.04.2021 18:50