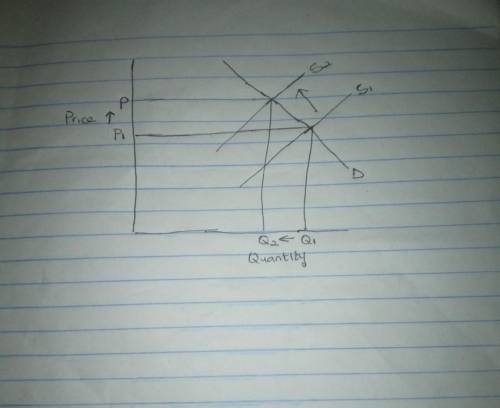

About 1.4 billion pounds of American, cheddar and other kinds of cheese is socked away at cold-storage warehouses across the country, the biggest stockpile since federal record-keeping began a century ago...Many [cheese companies] are paying to store their excess cheese in hopes demand and prices will improve. Source: Heather Haddon, "America Can't Move Its Cheese," Wall Street Journal, December 17, 2018. What effect did the strategy of warehousing cheese have on the supply of cheese? Using the line drawing tool, show the effect of cheese producers storing cheese in warehouses rather than offering it for sale. Properly label your line. Carefully follow the instructions above, and only draw the required object

Answers: 2

Another question on Business

Business, 22.06.2019 02:00

Corporations with suppliers, vendors, and customers all over the globe are referred to as : a) global corporations b) international corporations c) multinational corporations d) multicultural corporations

Answers: 2

Business, 22.06.2019 03:00

How does having a flexible mind you become a better employee? a. it you become more honest toward work. b. it you become a team player. c. it you learn new things that will better your performance. d. it you to finish your work on time. e. it you reach work on time

Answers: 1

Business, 22.06.2019 11:20

Lusk corporation produces and sells 14,300 units of product x each month. the selling price of product x is $25 per unit, and variable expenses are $19 per unit. a study has been made concerning whether product x should be discontinued. the study shows that $72,000 of the $102,000 in monthly fixed expenses charged to product x would not be avoidable even if the product was discontinued. if product x is discontinued, the annual financial advantage (disadvantage) for the company of eliminating this product should be:

Answers: 1

Business, 22.06.2019 11:40

Zachary company produces commercial gardening equipment. since production is highly automated, the company allocates its overhead costs to product lines using activity-based costing. the costs and cost drivers associated with the four overhead activity cost pools follow: activities unit level batch level product level facility level cost $ 64,800 $ 27,730 $ 15,000 $ 154,000 cost driver 2,400 labor hrs. 47 setups percentage of use 11,000 units production of 780 sets of cutting shears, one of the company’s 20 products, took 240 labor hours and 7 setups and consumed 15 percent of the product-sustaining activities. required: (a) had the company used labor hours as a company wide allocation base, how much overhead would it have allocated to the cutting shears? (b) how much overhead is allocated to the cutting shears using activity-based costing? (c) compute the overhead cost per unit for cutting shears first using activity-based costing and then using direct labor hours for allocation if 780 units are produced. if direct product costs are $150 and the product is priced at 30 percent above cost for what price would the product sell under each allocation system? (d) assuming that activity-based costing provides a more accurate estimate of cost, indicate whether the cutting shears would be over- or underpriced if direct labor hours are used as an allocation base. explain how over-or undercosting can affect vaulker's profitability. (e) comment on the validity of using the allocated facility-level cost in the pricing decision. should other costs be considered in a cost- plus pricing decision? if so, which ones? what costs would you include if you were trying to decide whether to accept a special order?

Answers: 1

You know the right answer?

About 1.4 billion pounds of American, cheddar and other kinds of cheese is socked away at cold-sto...

Questions

Mathematics, 29.10.2020 23:50

Business, 29.10.2020 23:50

History, 29.10.2020 23:50

Mathematics, 29.10.2020 23:50