Business, 11.06.2021 22:30 tarhondaeiland4122

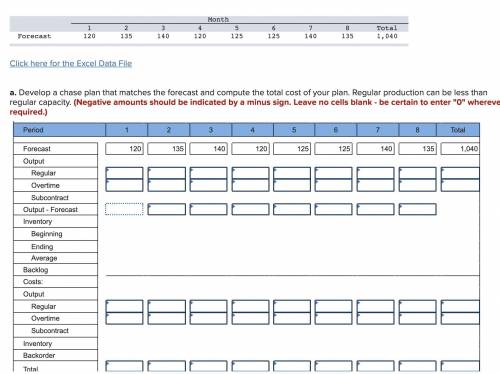

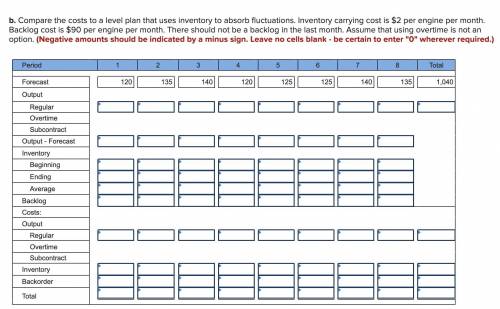

Manager T. C. Downs of Plum Engines, a producer of lawn mowers and leaf blowers, must develop an aggregate plan given the forecast for engine demand shown in the table. The department has a regular output capacity of 130 engines per month. Regular output has a cost of $60 per engine. The beginning inventory is zero engines. Overtime has a cost of $90 per engine.

Answers: 1

Another question on Business

Business, 22.06.2019 06:00

Select the correct answer a research organization conducts certain chemical tests on samples. they have data available on the standard results. some of the samples give results outside the boundary of the standard results. which data mining method follows a similar approach? o a. data cleansing ob. network intrusion o c. fraud detection od. customer classification o e. deviation detection

Answers: 1

Business, 22.06.2019 06:40

Vintage fun reproduces oldminusfashioned style roller skates and skateboards. the annual production and sales of roller skates is 950 units, while 1,750 skateboards are produced and sold. the company has traditionally used direct labor hours to allocate its overhead to products. roller skates require 2.5 direct labor hours per unit, while skateboards require 1.25 direct labor hours per unit. the total estimated overhead for the period is $114,300. the company is looking at the possibility of changing to an activityminusbased costing system for its products. if the company used an activityminusbased costing system, it would have the following three activity cost pools: the overhead cost per skateboard using the traditional costing system would be closest to: a. $9.31. b. $65.31. c. $25.05. your answer is not correct.d.

Answers: 2

Business, 22.06.2019 07:50

In december of 2004, the company you own entered into a 20-year contract with a grain supplier for daily deliveries of grain to its hot dog bun manufacturing facility. the contract called for "10,000 pounds of grain" to be delivered to the facility at the price of $100,000 per day. until february 2017, the supplier provided processed grain which could easily be used in your manufacturing process. however, no longer wanting to absorb the cost of having the grain processed, the supplier began delivering whole grain. the supplier is arguing that the contract does not specify the type of grain that would be supplied and that it has not breached the contract. your company is arguing that the supplier has an onsite processing plant and processed grain was implicit to the terms of the contract. over the remaining term of the contract, reshipping and having the grain processed would cost your company approximately $10,000,000, opposed to a cost of around $1,000,000 to the supplier. after speaking with in-house counsel, it was estimated that litigation would cost the company several million dollars and last for years. weighing the costs of litigation, along with possible ambiguity in the contract, what are three options you could take to resolve the dispute? which would be the best option for your business and why?

Answers: 2

Business, 22.06.2019 12:10

The cost of the beginning work in process inventory was comprised of $3,000 of direct materials, $10,000 of direct labor, and $10,000 of factory overhead. costs incurred during the period were comprised of $15,000 of direct materials costs, and $100,000 of conversion costs. the equivalent units of production (eup) for the period were 9,000 for direct materials and 6,000 for conversion. the costs per eup were:

Answers: 3

You know the right answer?

Manager T. C. Downs of Plum Engines, a producer of lawn mowers and leaf blowers, must develop an agg...

Questions

Mathematics, 30.08.2019 21:00

Mathematics, 30.08.2019 21:00

History, 30.08.2019 21:00

Mathematics, 30.08.2019 21:00

Social Studies, 30.08.2019 21:00

History, 30.08.2019 21:00

Biology, 30.08.2019 21:00

Mathematics, 30.08.2019 21:00

History, 30.08.2019 21:00

Mathematics, 30.08.2019 21:00

Arts, 30.08.2019 21:00

Mathematics, 30.08.2019 21:00

History, 30.08.2019 21:00